Find Molding Profiles, Wood Trim Profiles, Moulding Profiles on Industry Directory, Reliable Manufacturer/Supplier/Factory from China.

New Products

| Delivery Time: | 30 Days |

|---|

Model No.: TCCM003

Widely Used PU Cornice Mouldings with fine workmanship Specification

Widely Used PU Cornice Mouldings with fine workmanship Specification | Detail Specifications |

Brand: | TIARA | ||

SKU#: | TCCM003 | ||

Title: | Carved Cornice Moulding | ||

Material: | Polyurethane(PU) | ||

Density: | 220kg/m³ | ||

Color: | White;Gold;Silver | ||

Size: | Length(cm) | Height(cm) | Projection(cm) |

240 | 13.5 | 10 | |

Net Weight: | 1.15kg/pcs | ||

Packing: | Pearl bubble paper inside and carton outside | ||

Packing Quantity | 24pcs/ctn | ||

Lead time: | 30-40 days after deposit received | ||

Payment terms: | 30% T/T in advance ,70% before the shipment,or irrevocable L/C at sight | ||

MOQ: | 100 units | ||

OEM: | yes | ||

| Product Images |

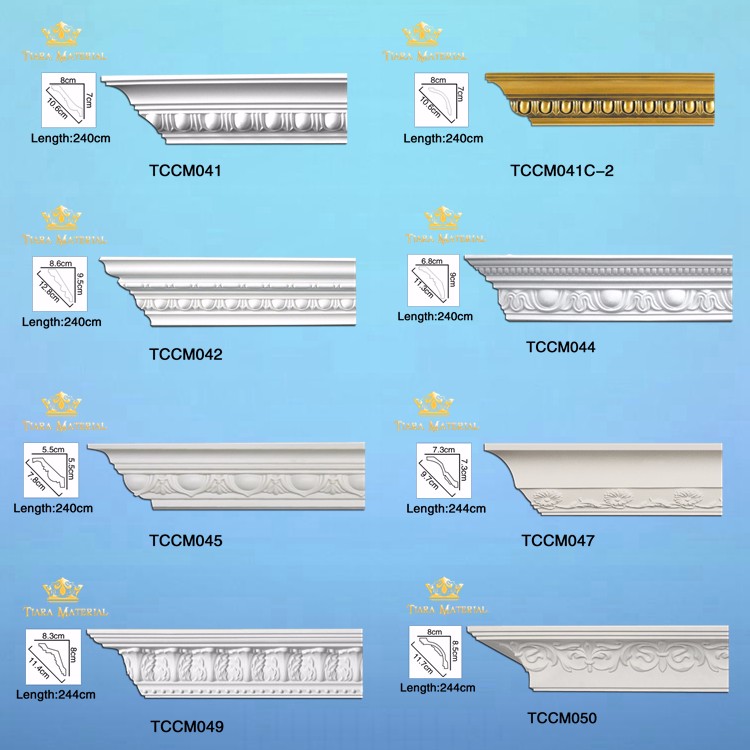

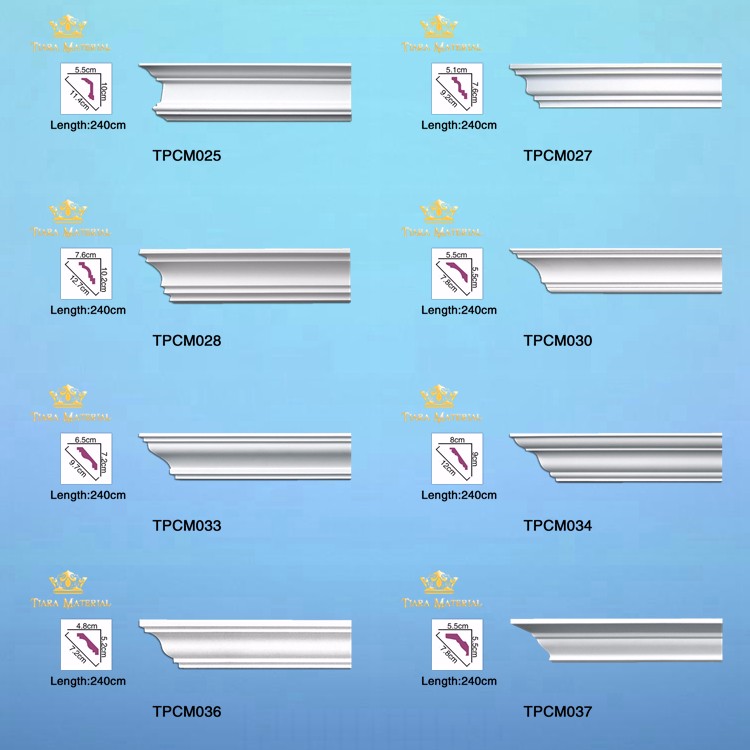

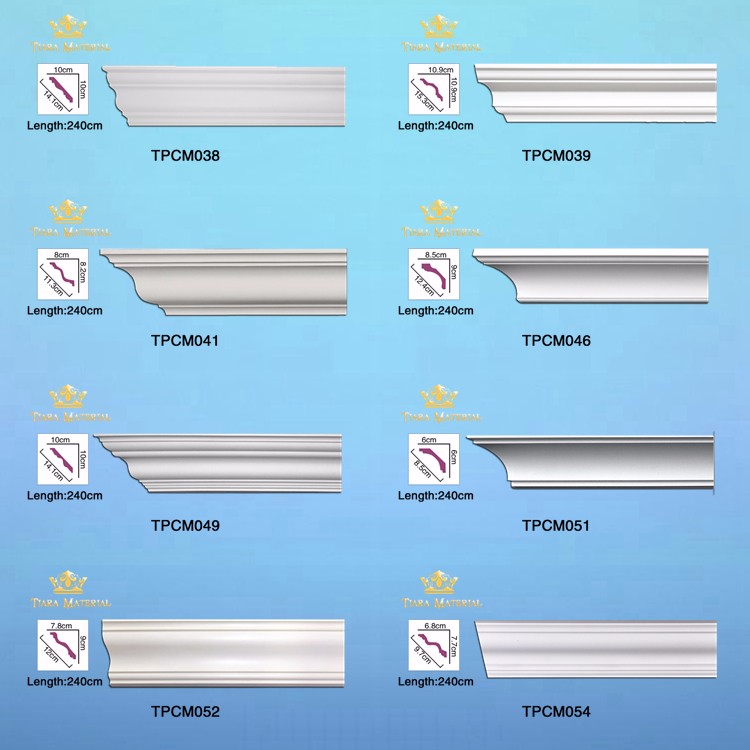

| Related Products |

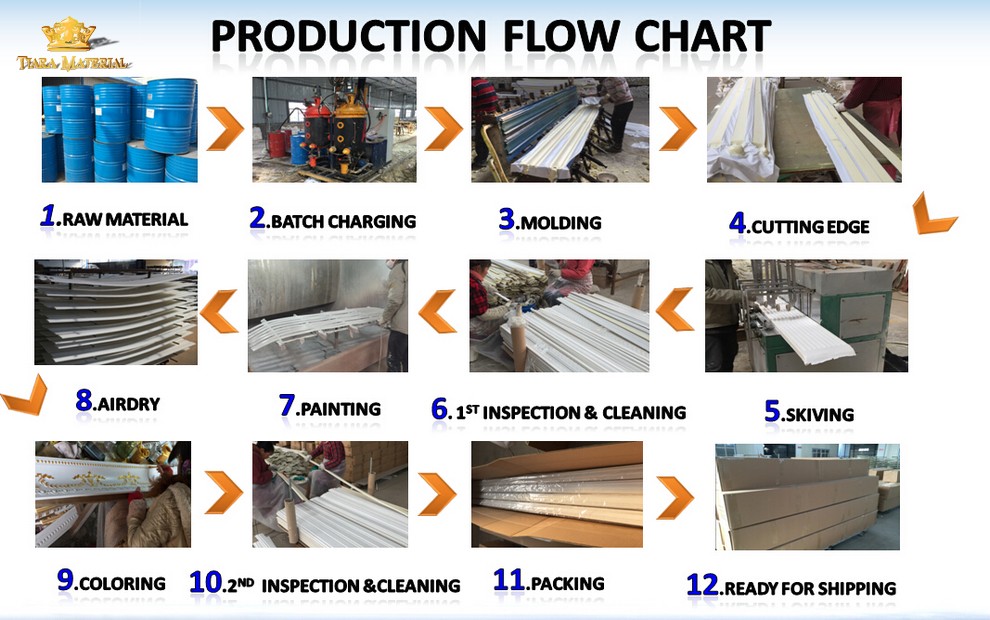

| Production Flow Chart |

| Decoration Views |

Packing & Shipping

Packing & Shipping | Packing Details |

PU Advantages

PU Advantages | Advantages of Polyurethane Decorative Materials |

Polyurethane: | Plaster: | Wood / MDF: | |

Material: | - Lightweight | - Heavy and fragile | - Different types of wood |

- Easy to handle | - Requires expert craftsman skills | - Absorbs water / prone to deformation | |

- Sturdy and durable | - Custom made | - Easy but heavy to manipulate | |

- Recyclable | - Recyclable | ||

Quality: | - Water resistant | - Fine detail, made to order | - Knock resistant |

- Knock resistant | - Stable material - requires high quality raw material | - Warps and deforms over time | |

- Sharp details | - Cracks with humidity fluctuations | ||

- Matt and smooth finish (no sanding required) | |||

- Available in stock, quick delivery | |||

Installation: | - Easy and quick to handle and install | - Requires skilled professionals | - Requires knowledge of wood properties |

- Already primed, ready to paint | - Time consuming | - Absorbs paint | |

- Intensive and dirty installation |

Plaster (Gypsum) mouldings | Polyurethane mouldings |

| Difficult to work with – very heavy Cannot be used on lowered ceilings / plaster board (it is too heavy). Installation requires at least two people Time-consuming Installation A heavy and difficult job that takes a lot of time. Dirty A lot of water and dust. Difficult to use for refurbishment. Design features are not very detailed Very fragile Usually delivered ‘wet’ Must be left to dry before installing – for up to two weeks. Joints crack Not suitable for humid areas Does not come with a Primer coat Difficult to paint – no smooth surface Gypsum absorbs the paint – up to three coats are necessary. Difficult to use on curved walls & ceilings | Easy to install Can be installed on any type of ceiling. Can lower structural weight greatly in big buildings. Installation can be done by one person. Time-saving Can be installed up to three times faster. Clean Only glue is used. Perfect for new build and refurbishment. Very detailed design features. Strong and durable Ready for immediate use Available from stock for next day delivery. No cracks Can be used in humid areas Comes pre-primed Easy to paint – smooth surface. Any kind of effect can be achieved on our products. Does not absorb paint – only one coat needed |

| About TIARA Building Material |

Why Chose TIARA

Why Chose TIARA | We Are Worth Your Trust ! |

| Frequently Asked Questions |

| Sales Director AT YOUR SERVICE ! |

Mr. Leo Wu Sales Director Skype ID:leonidas1010 Tele Phone:+86 516 83869109 Cell phone: +86 14752298897 Whatsapp: +86 14752298897 Website: Alibaba:

Mr. Leo Wu Sales Director Skype ID:leonidas1010 Tele Phone:+86 516 83869109 Cell phone: +86 14752298897 Whatsapp: +86 14752298897 Website: Alibaba:  Contact us if you need more details on Cornice Mouldings. We are ready to answer your questions on packaging, logistics, certification or any other aspects about PU Cornice Mouldings、Polyurethane Cornice Mouldings. If these products fail to match your need, please contact us and we would like to provide relevant information.

Contact us if you need more details on Cornice Mouldings. We are ready to answer your questions on packaging, logistics, certification or any other aspects about PU Cornice Mouldings、Polyurethane Cornice Mouldings. If these products fail to match your need, please contact us and we would like to provide relevant information. Product Categories : PU Carved Cornice Moldings